Collins Aerospace, an arm of RTX, has completed a critical milestone with its new Enhanced Power and Cooling System (EPACS) for the multi-role fighter F-35 Lightning II. Cooling requirements gradually rise when the F-35 obtains new subsystems such as sensors, electronics, weapons, etc.

The F-35 now employs Honeywell Aerospace’s Power and Thermal Management System (PTMS). Cooling is accomplished by circulating air from the engine compressor through heat exchangers. A cooling fluid travels through the heat exchangers and the aircraft’s essential electrical subsystems, including the radar. The pilot’s cabin is likewise air-conditioned with air from the PTMS.

PTMS also ensures that the aircraft’s main engine and emergency/auxiliary power are started, as needed, during ground maintenance. It supplies power in the event of a main engine failure during flight and keeps the avionics, cockpit instruments, all aircraft controls, and other systems operational. It facilitates engine restart during flying. It also delivers pressurised air to pressurise the pilot’s cabin and anti-gravity suit.

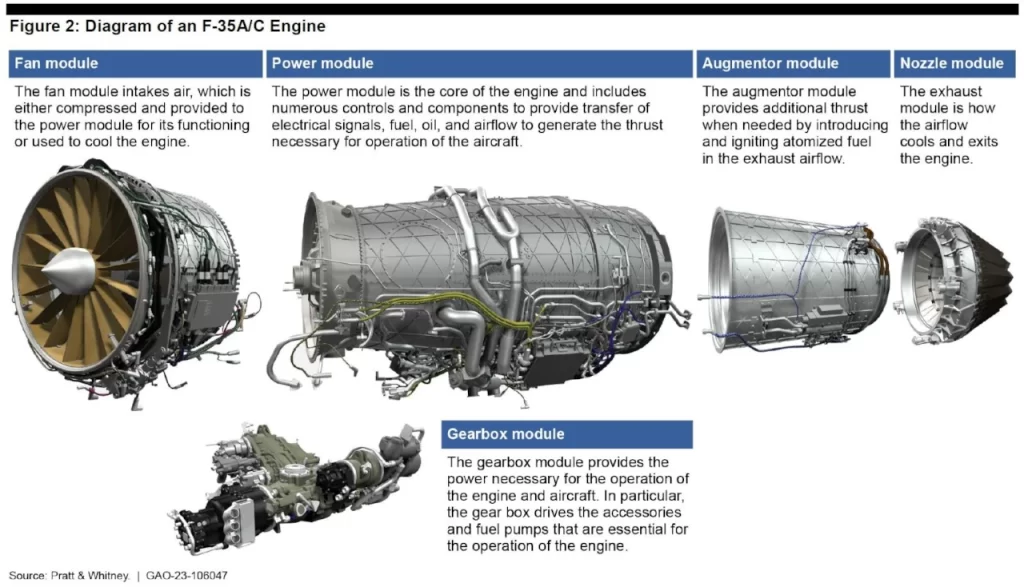

However, contrary to previous expectations, PTMS demands more air for aircraft system cooling. This causes the F135 engine to work under greater stress, resulting in a shorter engine life than expected. Pratt & Whitney designed the F135 to deliver a specific volume of air for PTMS, as specified by Lockheed Martin at the start of the programme. However, in 2008, these standards proved insufficient. It was no longer possible to modify the F135 engine.

According to Breaking Defence, the F135 was designed with a cooling capacity of 15 kW. However, it now has a cooling capacity of 30 kW. To fully utilise the F-35 Block 4, a capacity of 48 kW, preferably 60 kW, is required.

According to the Government Accountability Office’s (GAO) May 2023 report, future versions of the F-35, including additional weapons and sensors, would require a new or enhanced PTMS system.

These cooling issues will undoubtedly intensify when the programme introduces new capabilities to the aircraft. According to the GAO, modernisation capabilities, including those currently installed in Block 4 and those planned for 2035, require even more cooling capacity and air pressure than PTMS and the engine can handle.

Already, larger cooling demands than planned are reducing engine life and increasing expenses. According to the GAO, cooling issues have increased the expected programme cost by $38 billion over its entire life cycle, owing mostly to decreased engine life.

The programme must update PTMS by 2029 to enable the capabilities predicted for 2035 and modernise the engine to reduce life cycle costs. The existing engine and PTMS architecture will not provide sufficient cooling capacity to support further capabilities projected after 2029. If the programme does not update PTMS by 2029, it will be unable to support new capabilities anticipated for 2035 and after that. In contrast, programme officials said the present engine could sustain the capabilities intended for 2035, albeit with a much shorter engine life. As a result, programme managers noted that the engine would need to be modernised to extend its life and potentially prevent some of the $38 billion in additional life cycle costs, according to the GAO.

The first step towards repair is to upgrade the engine through the ECU (Engine Core Upgrade) program. This addresses acute engine loading issues in comparison to the prior assumptions. However, the Pentagon has yet to choose how to proceed with the cooling system. PTMS modernisation and EPCS implementation are both possibilities on the table. In any case, the F-35 needs more powerful cooling.

There are large sums of money involved. Honeywell PTMS, of course, strongly defends their system. The PTMS system is extensively integrated into the F-35 aircraft’s overall design and system architecture, allowing it to interact flawlessly with other important components and subsystems. By retaining PTMS, the company will avoid years of lengthy and very complex rework and testing, avoiding the costly delays that could result from switching to a completely different system.

Honeywell estimated the cost of replacing PTMS to be $3 billion. When it comes to replacing PTMS and deploying EPACS, it’s a three billion dollar bill because one has to replace all the spare parts, everything in the fleet, all the support equipment, and all the training, said Matt Milas, the business leader of Honeywell’s military division. He also mentioned the “invasive adjustments” required to the aircraft if the PTMS is changed.

PTMS is not a ‘plug and play’ system; it is the F-35’s heart and circulatory system, and it is strongly integrated into the F-35 design, initially meant to operate in 14 different operational modes, Milas added, underlining that the system matches the aircraft’s current requirements.

According to Jill Albertelli, president of Pratt & Whitney military engines division, the F135 ECU, when combined with the updated PTMS for the F-35, can produce 80 kW or more of cooling power, exceeding the F-35’s total power and cooling requirements over the program’s duration.

In addition, Honeywell is working with Lockheed Martin to provide an extra 17 kW of cooling power for the F-35, bringing the total to 47 kilowatts for the F-35 Block 4.

Henry Brooks, president of Collins Aerospace’s Power & Controls group, states that F-35 planes are the backbone of partner forces worldwide. Cooling capabilities must be greatly expanded to update this platform with innovative technologies capable of responding to new threats. With a more efficient thermodynamic cycle, the EPACS system can deliver the extra cooling required by the F-35, extending the aircraft’s lifespan for decades.

EPACS incorporates Collins Aerospace’s air cycle system, an electric power generator and regulator, and a Pratt & Whitney auxiliary power unit. A few days ago, the company stated that EPACS had reached 80 kW of cooling capacity. The device is also projected to take less air from the compressor, improving fuel consumption and range. Supporters say EPACS should offer adequate cooling power throughout the F-35’s lifecycle.

It is unclear how the Pentagon will determine whether to update PTMS or implement a new system. For now, the Pentagon is undertaking market research; it has filed a Request For Information for a cooling system for the F-35 with a capacity of 62 kW, possibly increasing to 80 kW later on. This solution should be available by 2032, while Collins Aerospace believes EPACS may start manufacturing as early as 2030.