The pursuit of self-reliance in aerospace and defence has long been a key part of India’s national security strategy. A notable advancement is now evident in the domestic development of an advanced high-thrust jet engine, designed to power fifth-generation fighter aircraft and other future combat platforms.

For decades, propulsion has remained the Achilles’ heel of Indian aerospace development. While aircraft designs and airframes have evolved, Tejas, AMCA (Advanced Medium Combat Aircraft), and UAV projects being prime examples, the absence of a fully indigenous, world-class engine has limited progress. Today, that barrier is being broken.

The new powerplant signifies not just technological achievement but also a declaration of intent: India is committed to designing, developing, and deploying its own propulsion systems, independent of external dependencies.

Co-Design and Collaboration: Building the Foundation

Unlike earlier projects that were isolated and limited in scope, the current initiative thrives on a co-design and co-development approach.

The Engine House and Gas Turbine Research Establishment (GTRE) are leading the effort.

Academia and industry are closely integrated into the program, uniting theoretical innovation, applied engineering, and manufacturing excellence under one common umbrella.

The guiding principle is a balance of know-how (technical processes) and know-why (scientific reasoning), ensuring that the capability is not limited to producing one product but rather maintaining an ecosystem of ongoing innovation.

This collaboration guarantees that the engine is not a standalone achievement but part of a modular family, capable of upgrades and iterations to meet future demands.

Engine Design: Features and Innovations

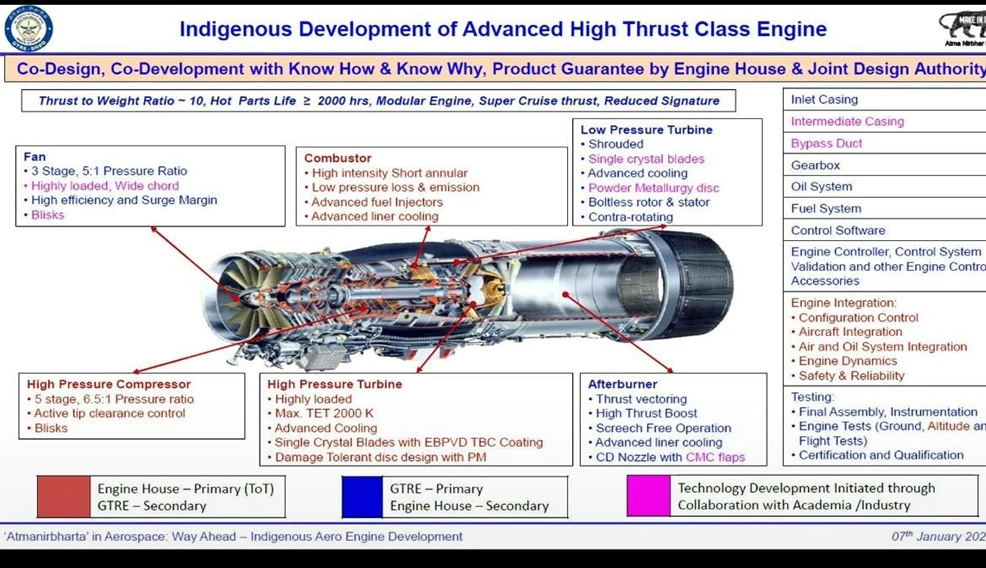

The new engine design demonstrates India’s advances in fifth-generation propulsion. It fulfills the main needs of high thrust, fuel efficiency, reliability, stealth features, and modularity, distinguishing it from earlier indigenous developments.

Key Performance Benchmarks

- Thrust-to-weight ratio: 10:1

- Hot parts life: 2000+ hours

- Super-cruise capability: sustained supersonic flight without afterburner

- Low radar/infrared signature: enabling stealth integration

Let us break down the design components:

Fan

- Three-stage design with a 5:1 pressure ratio.

- Wide chord, low-drag blades engineered for high surge margin.

- Incorporation of advanced blisks reduces part count, improves efficiency, and lowers maintenance.

High-Pressure Compressor (HPC)

- Eleven stages delivering a 24:1 pressure ratio.

- Variable stator vanes allow optimisation across speeds and altitudes.

- Close tolerances and advanced materials maximise aerodynamic efficiency.

Combustor

- A compact, high-intensity annular combustor.

- Designed for lean-burn operation, lowering emissions and pressure losses.

- Advanced fuel injection ensures complete combustion while maintaining flame stability.

High Pressure Turbine (HPT)

- Operates at inlet temperatures above 2000K, a benchmark achieved only by top global engines.

- Airfoil geometry optimised for cooling and stress distribution.

- Single-crystal blades with advanced EBP/VD thermal barrier coatings extend life.

Low-Pressure Turbine (LPT)

- Multi-stage system with shrouded, cooled blades.

- Variable geometry permits adaptive flow control to maximise thrust or efficiency as required.

Afterburner

- Provides thrust augmentation critical for combat scenarios.

- Features variable area nozzles for optimised performance and stealth shaping.

- Cooling provisions ensure reliability during prolonged high-thrust operations.

Together, these elements mark a generational leap from earlier indigenous efforts like the Kaveri engine, which fell short of operational parameters but provided crucial lessons.

Digital Control and Safety Integration

Modern propulsion cannot succeed without equally advanced control. The engine incorporates a Full Authority Digital Engine Control (FADEC) system that:

- Optimises performance dynamically based on mission parameters.

- Interfaces seamlessly with the aircraft’s avionics suite, enabling real-time adjustments.

- Incorporates health monitoring and automated diagnostics, ensuring predictive maintenance and minimising downtime.

- Embeds robust safety protocols, allowing the engine to operate reliably under combat stress, varying altitudes, and extreme weather.

- This level of digital integration transforms the engine into an intelligent system, reducing pilot workload while enhancing aircraft survivability.

The Technology Development Ecosystem

The real strength of this project lies in its ecosystem-based approach:

- Engine House. Provides transfer of technology, design authority, and quality assurance.

- GTRE. Leads development, testing, and certification.

- Academia. Contributes to computational fluid dynamics, materials research, and thermal analysis.

- Industry. Manufactures precision components, from turbine blades to FADEC modules, ensuring scalability and repeatability.

This multi-institutional ethos not only builds technical expertise but also nurtures a generation of Indian engineers and scientists trained in cutting-edge propulsion systems. The spillover benefits to civil aviation, UAV engines, and industrial turbines will be substantial.

Strategic Significance: Developing a Self-Reliant High-Thrust Class Jet Engine. This Project has significant implications for India’s defence and industry, representing a strategic shift in the country’s aerospace strengths.

Operational Independence. A Strategic Shift in India’s Defence. India’s long-standing dependence on imported engines, especially from the US, France, and Russia, has been a strategic weak point. Developing this indigenous high-thrust jet engine marks a key move towards operational independence, eliminating the risk of sanctions or export restrictions that could halt programs suddenly.

Platform Growth. The Advanced Medium Combat Aircraft (AMCA) and 6th-generation concepts will need high-thrust, stealth-compatible engines. An indigenous engine provides design freedom without relying on foreign technology.

Export Potential: Expanding India’s Footprint in Global Defence Markets. Once proven, India’s indigenous high-thrust class jet engine could become a valuable export, providing engines for allied nations’ light and medium fighters, drones, and training aircraft. This not only boosts India’s global standing but also creates significant economic opportunities.

Industrial Multiplier. The project promotes metallurgy, precision engineering, digital electronics, and computational sciences. These fields will benefit from spin-offs into automotive, energy, and commercial aviation.

Challenges Ahead

Despite the progress, hurdles remain.

Materials Technology. Single-crystal blades and thermal barrier coatings are notoriously tricky to master. India must increase production while maintaining consistent quality.

Testing Infrastructure. Extensive ground and flight testing are necessary before full certification. This involves using wind tunnels, test beds, and thorough data validation.

Sustained Funding. Engine development is a long-term, capital-intensive process that requires government commitment throughout political cycles.

Global Competition. Matching or surpassing engines like the Pratt & Whitney F119 or the Russian AL-41F1 demands relentless innovation.

Yet, each of these challenges is surmountable with sustained focus and strategic patience.

Comparative Perspective

Global fifth-generation fighters like the US F-22 and F-35, Russia’s Su-57, and China’s J-20 are powered by engines that took decades of research and development. India’s entry into this field places it among the few nations with indigenous capabilities.

Where the Kaveri engine faltered, the present program succeeds by:

- Seeking parity with global leaders while laying the groundwork for sixth-generation propulsion. Leveraging international collaboration without over-dependence.

- Integrating digital simulation tools for faster iterations.

- Building a modular architecture for incremental upgrades.

- India’s effort is thus evolutionary yet bold.

Conclusion

The indigenous development of a high-thrust class engine is more than an engineering achievement; it is a strategic milestone. By combining co-design philosophy, cutting-edge materials, advanced digital controls, and a collaborative ecosystem, India is charting its own course toward fifth-generation propulsion.

For the Indian Air Force and Navy, this means increased confidence in long-term planning and fleet maintenance. For the nation, it signifies less dependency, improved industrial capacity, and a more assertive stance in the global aerospace sector.

As India advances into the era of fifth-generation fighters and beyond, this engine will power not only aircraft but also the vision of an Atmanirbhar Bharat in aerospace. The nation can fly higher, faster, and farther through its own innovation.