The certification campaign for Russia’s domestically developed SJ-100 short-haul regional airliner has reached a critical stage, representing an important step in the nation’s post-sanctions civil aviation strategy. By the end of December 2025, the program achieved a reported 92 percent certification readiness level, signifying that the majority of technical, regulatory, and operational prerequisites have been satisfied. This progress demonstrates the collaborative efforts of manufacturers, regulators, and suppliers in advancing a domestically developed successor to the Sukhoi Superjet 100 toward full commercial deployment.

In December alone, three SJ-100 prototypes were simultaneously airborne, a rare and significant indication of progress in the certification program. Multiple aircraft operating concurrently enable engineers to validate various systems simultaneously, thereby shortening development timelines and minimizing reliance on a single test platform. This approach indicates that the program has advanced beyond isolated experimental flights and has entered a structured, multi-aircraft validation stage.

The SJ-100 project is broadly recognized as an essential component of Russia’s aviation import substitution strategy. Unlike previous versions of the Superjet, which depended significantly on Western suppliers, the SJ-100 is engineered to function with domestically manufactured systems, engines, avionics, and support infrastructure. Its successful certification would signify not only a technical accomplishment but also a strategic milestone, guaranteeing the continuity of regional air transportation amidst limited international conditions.

Active Certification Flights and Test Aircraft Roles

At the core of the ongoing certification initiative is aircraft 79021, which is chiefly dedicated to evaluating the automatic landing system. This system is essential for approval, especially for operations conducted in adverse weather conditions and at regional airports with limited ground-based navigation aids. Automatic landing certification includes multiple precision approaches, system redundancy assessments, and fault-tolerance validations, rendering it one of the most rigorous phases of the flight test program.

In January, this aircraft is expected to be accompanied by aircraft 97024, the first production-standard SJ-100. The involvement of a production aircraft signifies an important milestone: regulatory authorities must confirm that the configuration proceeding to serial production performs identically to the tested prototypes. This step guarantees that performance, control, and system reliability remain consistent as the aircraft transitions from the test fleet to airline operations.

Another important factor to the certification process is aircraft 94024, which, during a December flight, climbed to an altitude of 12,276 meters. High-altitude testing is vital for verifying pressurization integrity, engine performance, environmental control systems, and aerodynamic stability in proximity to the upper boundaries of the flight envelope. These evaluations additionally generate data concerning emergency procedures and operational limitations, which will subsequently be incorporated into flight manuals and certification documents.

Industrial Collaboration in Aircraft Development

The SJ-100 program exemplifies an exceptionally extensive industrial partnership. According to publicly available data, forty-one companies are engaged in the manufacturing and assembly of the aircraft. These companies provide a comprehensive range of components, including main structural assemblies, propulsion systems, avionics, landing gear, hydraulics, and software.

This decentralized industrial model fulfills two distinct objectives. First, it enables Russia’s aerospace industry to preserve and enhance specialized expertise across various enterprises. Secondly, it reduces dependence on a single supplier, thereby enhancing resilience to supply chain disruptions. However, overseeing such an extensive network of contributors also elevates coordination complexity, rendering the high certification preparedness level especially significant.

Logistical activities at the end of December underscored the high degree of synchronization achieved between the production and testing processes. On December 20, one of the aircraft was dispatched to Ulyanovsk for repainting, and by December 29, it had returned to Zhukovsky in a new white livery. Although paintwork may seem superficial, it is typically undertaken only after the aircraft’s structural and systems configuration has largely stabilized, thereby further indicating confidence in the maturation of the program.

Prospects for an Extended SJ-100 Variant

Beyond the certification of the baseline model, PJSC Yakovlev has affirmed that it is exploring the potential development of a stretched SJ-100 variant accommodating 120 to 130 passengers. Although still in the conceptual phase, this proposal presents a long-term vision for the platform rather than a singular model solution.

An extended variant would enable airlines to augment passenger capacity without the need to develop an entirely new aircraft model, thereby potentially lowering training, maintenance, and spare-part expenses. From a market perspective, this could position the SJ-100 family more directly against larger regional jets and basic narrow-body aircraft.

Such a development would necessitate structural reinforcement, assessment of the landing gear, potential engine propulsion modifications, and renewed certification procedures. Nevertheless, the mere fact that this option is being considered indicates increasing confidence in the SJ-100 as a versatile and scalable aircraft platform.

Regulatory Supervision and Certification Status

The Federal Air Transport Agency (Rosaviatsia) serves a pivotal function in supervising the certification process of the SJ-100. Its head, Dmitry Yadrov, has affirmed that certification flights are progressing as scheduled and that no significant delays are impacting the overall timeline.

Certification extends beyond solely the performance of the airframe. It additionally includes system reliability, software validation, pilot-aircraft interaction, maintenance protocols, and adherence to safety standards. Each successfully completed test phase diminishes uncertainty and advances the program toward obtaining formal type certification, a prerequisite for commercial operations.

Rosaviatsia’s role also encompasses assessing the integration of the SJ-100 into current airline fleets, including its compatibility with airport infrastructure, maintenance facilities, and pilot training programs. This comprehensive approach is vital to ensure that certification results in practical applicability rather than solely serving as a technical formality.

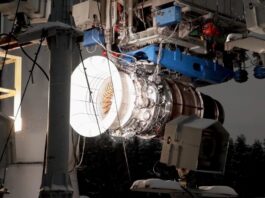

PD-8 Engine Testing Approaches Completion

Along with the airframe certification, the testing of the PD-8 turbofan engine, expressly developed to power the SJ-100, is also underway. According to Rosaviatsia, the engine’s testing program is in its final phase and is advancing according to schedule.

The PD-8 constitutes a vital component of Russia’s strategy for maintaining aviation independence. Replacing the Franco-Russian SaM146 engine with a completely domestically produced alternative removes dependence on foreign suppliers for spare parts, maintenance approvals, and ongoing support. Engine certification encompasses comprehensive bench testing, endurance assessments, in-flight performance verification, and safety demonstrations under anomalous operating scenarios.

The effective completion of PD-8 certification would not only facilitate the delivery of SJ-100 aircraft but also potentially pave the way for the engine’s application on additional aircraft platforms in the future. This would further improve economies of scale and diminish lifecycle costs across various programs.

The Issue of Re-Engining Current Superjets

One of the most debated topics regarding the SJ-100 and PD-8 program is the possible re-engining of existing SSJ-100 aircraft currently equipped with SaM146 engines. The Ministry of Industry and Trade has affirmed that this option is under review; however, substantial uncertainties persist.

Deputy Minister Gennady Abramenkov has recognized that the main challenge lies not in technical feasibility but in securing funding and delineating responsibilities. Although the United Aircraft Corporation and the United Engine Corporation are ready to engage in research and development, the more comprehensive issue concerns the manner in which modernization will be applied to specific aircraft and the allocation of the related expenses.

Re-engining constitutes a complex procedure. It encompasses structural alterations, system integration, updated software, new certifications, and modifications to maintenance procedures. These expenses can constitute a significant proportion of the cost of a new aircraft, prompting airlines to exercise caution in committing to such programs absent obvious financial incentives or governmental assistance.

Interest and Economic Factors of Airlines

Despite these obstacles, Rosaviatsia has affirmed that all principal operators of the Superjet 100 have demonstrated interest in the PD-8 alternative. For airlines, the attractiveness resides in ensuring a reliable supply chain, consistent maintenance expenses, and the enduring viability of their fleet within the framework of domestic support policies.

Nevertheless, interest does not inherently equate to commitment. Airlines are required to assess fuel efficiency, reliability, downtime, and comprehensive lifecycle economics prior to determining whether re-engining is advantageous in comparison to operating existing engines until the end of their service life or transitioning to newly manufactured SJ-100 aircraft.

This economic balancing challenge is further exacerbated by the presence of numerous existing Superjets equipped with additional foreign-sourced systems. Replacing engines alone may not entirely remove reliance on imported components, thereby constraining the tangible advantages of partial modernization.

Divergent Expert Perspectives on Remotorization

Aviation specialists continue to hold differing opinions regarding the viability of large-scale re-engining. Some contend that substantial investment in modernizing a relatively small fleet of aircraft does not yield adequate returns, particularly given the anticipated entry into service of new SJ-100s equipped with entirely domestically developed systems.

Others argue that remotorization may function as a transitional measure, prolonging the operational lifespan of current fleets while the production of new aircraft increases. This discussion underscores the conflict between immediate operational requirements and overarching long-term industrial planning.

The government’s previous indication of potential funding for re-engining research at its own expense reflects an acknowledgment of the strategic importance of the PD-8 program. Whether this position develops into established funding mechanisms remains to be seen.

Prospects for Certification and Delivery

With certification readiness exceeding 90 percent and flight testing progressing rapidly, the SJ-100 program seems well-positioned to achieve certification in the near future. Industry expectations indicate that initial deliveries will commence following the attainment of regulatory sanction, with production volumes gradually increasing thereafter.

The achievement of the SJ-100 will be instrumental in determining the development of Russia’s regional aviation sector over the coming decade. It signifies not only a substitute for previous Superjet versions but also serves as a benchmark for the nation’s capacity to maintain sophisticated, high-technology manufacturing amid limited external circumstances.

Conclusion: A Strategic Aircraft at a Pivotal Moment

The SJ-100 certification program is at a pivotal point where technological accomplishment, economic considerations, and government policy converge. Progress in flight testing and engine development indicates that the aircraft is nearing operational readiness, while discussions regarding re-engining current fleets highlight the financial and strategic challenges involved.

If effectively certified and produced at scale, the SJ-100 has the potential to reinforce Russia’s regional air transport capacity and serve as a basis for future aircraft development. Simultaneously, unresolved issues regarding modernization funding and fleet transition strategies underscore that the program’s ultimate effectiveness will hinge as much on policy choices as on engineering achievements.