Development of the Russian high-thrust turbofan aircraft engine PD-35 started in 2017, marking one of the most ambitious initiatives in the history of domestic aircraft engine manufacturing. The aim of the program was to develop a high-performance propulsion system within the 35-ton-force thrust class, capable of satisfying the demands of future wide-body passenger aircraft and large transport airplanes. PD-35 was conceived as the first Russian-produced engine of this magnitude and simultaneously as the cornerstone for a comprehensive family of engines spanning a thrust range from 24 to 50 tons-force, thereby guaranteeing sustained technological independence from foreign power plants.

By early 2025, the program had entered a crucial stage: transitioning from the validation of calculated performance parameters to the assessment of the service life and reliability of essential components, signifying a move from theoretical confirmation to practical operational maturity.

The Technology Demonstrator and the First Test Phase

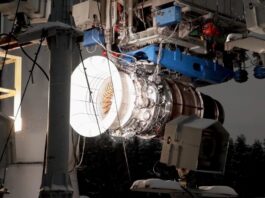

A major turning point in the PD-35 program was the development of a technology demonstrator engine. This demonstrator was assembled in 2023 and served as the central component of the original comprehensive test campaign. In 2024, it successfully concluded the first stage of ground testing at the all-weather open test stand OS-5 in the settlement of Novye Lyady near Perm—Russia’s largest test facility for engines in the 50-ton-thrust class.

During this phase, the demonstrator executed over 50 engine starts, consistently attaining takeoff power. The results verified the achievement of the target thrust of approximately 35 tons-force, confirmed the accuracy of the chosen design solutions, and exhibited strong concordance between the actual and predicted performance metrics.

These tests additionally enabled the validation of over 20 innovative technological solutions, the evaluation of thermodynamic and mechanical parameters, and the performance of endurance assessments on bearings and composite components.

Scientific Institutions and Core Technologies

Key technologies essential to the PD-35 program are being advanced by premier research institutions within the sector. Among the most significant contributors are:

The Central Institute of Aviation Motors named after P.I. Baranov (CIAM), Russia’s leading research center for aircraft propulsion systems, and the All-Russian Scientific Research Institute of Aviation Materials (VIAM) of the National Research Center “Kurchatov Institute,” which is instrumental in the development of advanced heat-resistant alloys and composite materials.

Consequently, PD-35 has evolved into an interdisciplinary initiative that consolidates multiple research institutions. It is not only an engine development initiative but a foundation for developing lasting expertise in materials science, manufacturing technologies, and advanced design methodologies.

Design Architecture and Key Technologies

By the beginning of 2025, PD-35 had developed into a comprehensive and well-defined modular engine platform. At its core, there is an integrated gas generator that is based on the scientific and technical foundation established for the PD-14 engine used on the MC-21 narrow-body aircraft.

One of the most notable features of the project has been the extensive integration of additive manufacturing technologies. Throughout 2025, in excess of 2,300 components for the demonstrator engine were manufactured employing selective laser melting and hybrid forming methods. These components underwent comprehensive assessments of their geometry, durability, and operational lifespan in accordance with forthcoming certification standards.

The engine’s material composition comprises nickel- and cobalt-based superalloys in the heated section, a newly developed domestically produced alloy for the low-pressure turbine shaft, and titanium and aluminum alloys for structural casings and assemblies.

Special emphasis has been placed on the composite materials used for the fan blades. With a fan diameter of 3,100 mm, the application of composite materials facilitated a weight reduction exceeding 600 kg in comparison to traditional titanium blade configurations, thereby markedly enhancing the engine’s overall efficiency performance.

Second Testing Phase: Durability and Service Longevity

In 2025, the program advanced to the second phase of bench testing for the PD-35 demonstrator. During this phase, the emphasis transitioned from verifying performance parameters to evaluating durability and reliability, especially for components produced using novel domestic materials.

Engineers from UEC-Aviadvigatel assessed the performance of high-pressure compressor blades, compressor assemblies, and the low-pressure turbine shaft. Testing was performed under maximal load conditions, with repeated assessments of performance stability and consistency—elements that are crucial for scaling production and preparing for certification testing.

Certification: The Approaching Threshold

Based on statements from Rostec management, the issuance of a type certificate for the PD-35 engine— the document that officially authorizes mass production and aircraft integration— is not anticipated before 2027 or 2028 at the earliest.

Certification signifies a crucial achievement. Only upon its completion can the program progress from experimental development to large-scale industrial manufacturing and deployment within aircraft programs. However, attaining this stage necessitates thorough endurance testing, enhancement of operational reliability, and validation of manufacturing procedures.

PD-35 and Aircraft Integration: Still Without a Dedicated Platform

As of 2025, no aircraft has been certified or officially approved for serial production with the PD-35 engine. The most commonly discussed concept is a modernized variant of the Il-96 wide-body aircraft, equipped with two PD-35 engines, resulting in a wholly domestically produced long-haul airliner.

However, this concept remains at the early study stage, with no verified contracts or finalized aircraft development program. Consequently, PD-35 presently serves chiefly as a technology demonstrator and development platform, rather than as a powerplant designed for imminent installation on a production aircraft.

PD-26: A New Engine Derived from the PD-35 Platform

Alongside the PD-35 program, the year 2025 signified the formal start of development activities for a derivative engine designated PD-26. In contrast to a clean-sheet design, PD-26 is being developed directly upon the technological foundation of PD-35, enabling engineers to leverage proven solutions, materials, and design methodologies.

PD-26 is designed as a more application-focused next-generation engine. It is designed for deployment on a forthcoming heavy military transport aircraft with a payload capacity of approximately 100 tons, as well as on a wide-body long-range passenger aircraft.

The engine architecture prioritizes modularity, unification of gas generators, extensive application of additive manufacturing techniques, ceramic matrix composites, and active blade cooling mechanisms. These characteristics render PD-26 more accurate in reflecting development schedules, cost management, and preparedness for actual deployment when contrasted with the larger and more intricate PD-35.

Beyond the aviation sector, PD-26 is also under consideration for ground-based energy systems and gas-compressor facilities, thereby substantially expanding its potential market. As stated by Russian government officials, designing an engine solely for a single aircraft variant would be economically impractical.

Potential Opportunities and a Probable Development Outlook

Based on the current information, several conclusions may be derived.

PD-35 as a Technological Foundation

The PD-35 program has already played a vital strategic role by establishing a technological foundation for high-thrust engines and strengthening advanced expertise within the Russian engine manufacturing sector. It has effectively transitioned from an independent development initiative to a fundamental technological platform for upcoming engine families.

Simultaneously, considering the difficulties related to certification, the lack of a confirmed aircraft platform, and extended timelines for operational deployment, a plausible scenario is that PD-35 will primarily serve as a testbed and technology provider rather than being broadly adopted as a production engine.

PD-26 as the Pragmatic Successor

PD-26, which builds directly upon PD-35 technologies while focusing on a more moderate engine class and well-defined application scenarios, possesses a greater likelihood of attaining earlier practical deployment. It is likely to become the inaugural engine to enter operational service—whether on a transport aircraft, a commercial airliner, or in industrial applications—based on the technological foundation established by the PD-35 program.

Final Remarks

The PD-35 program has accomplished major technological milestones, demonstrating the feasibility of innovative design solutions, materials, and manufacturing methods, and establishing a foundation for a forthcoming family of high-thrust engines. It represents a critical phase in the long-term development of Russia’s aircraft engine industry.

However, the definitive entry of PD-35 into aircraft service remains dubious and is largely contingent upon certification advancements and the development of an appropriate aircraft platform. In this context, PD-26 is likely to surpass PD-35 in operational deployment, becoming the first engine to convert PD-35’s technological advancements into practical implementations.