In late December, Rostec CEO Sergey Chemezov stated that the certification of the import-substituted Sukhoi SJ-100 was expected to be finalized in early 2026, with approximately twelve aircraft scheduled for delivery during the year. Shortly thereafter, further clarification was provided when the chief of the Federal Air Transport Agency stated that the certification timeline could be extended from late 2025 to March 2026, mainly owing to the ongoing certification process of the PD-8 engine.

These statements, although appearing contradictory, illustrate the dynamic process of a complex aircraft development program conducted within unprecedented industrial and geopolitical constraints. The SJ-100 is not simply a revised iteration of an existing aircraft; it is fundamentally a re-engineered platform built using domestic systems and technologies. As 2026 commences, the program reaches a pivotal point between extended testing phases and the transition to operational deployment.

Certification Deadlines and the Reality Behind Schedule Shifts

Previous public statements from Rostec and industry representatives consistently indicated certification by the end of 2025, with customer deliveries expected to commence in early 2026. This timeline was not created arbitrarily. It reflected the preliminary expectations derived from test progress, manufacturing readiness, and the projected maturation of the PD-8 engine program.

However, by October and once more towards the end of the year, Chemezov’s diction exhibited a noticeably increased level of caution. Instead of specifying an exact date, he started indicating that certification would be finalized within the first quarter of 2026. This transition does not signify a failure or the collapse of the program. Instead, it emphasizes a core principle of aircraft certification: that schedules are secondary to test results.

Certification deadlines are directly contingent upon the outcomes of flight tests, system validation, and the preparedness of industrial infrastructure. In the case of the SJ-100, the expedited substitution of foreign components with domestic alternatives markedly transformed the production and testing environment. Each newly localized system must be subjected to qualification, integration, and validation within the complete aircraft. Even minor discrepancies identified during late-stage testing may necessitate design modifications and supplementary verification flights.

Consequently, the certification timeline has evolved into a dynamic process rather than a fixed schedule, accurately representing technical realities rather than political or industrial optimism.

Import Substitution and Its Impact on Development Pace

The SJ-100 program is part of the larger context of Russia’s import substitution policy. Restrictions on the availability of foreign components compelled manufacturers to redesign essential systems that were previously obtained internationally, including engines, avionics, auxiliary power units, environmental control systems, and components of the flight control architecture.

This transformation has drastically changed production chains. Domestic suppliers needed to be established or expanded, manufacturing processes optimized, and certification documentation developed for components that had not previously been used on a commercial passenger aircraft. Although this approach enhances technological sovereignty over the long term, it also introduces greater short-term complexity.

The rate at which the SJ-100 is being introduced into service exemplifies this fact. The aircraft is not delayed due to failure to meet expectations; rather, it is delayed because it must fulfill them under significantly more stringent conditions than initially anticipated. Each subsystem substituted with a Russian counterpart enhances independence and increases the certification workload.

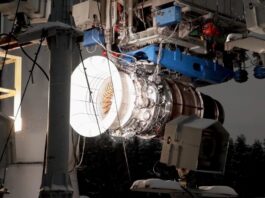

The PD-8 Engine: Performance, Testing, and Speculation

The PD-8 engine continues to be the most thoroughly examined component of the SJ-100 program. Designed to replace the SaM146, the PD-8 is integral to the aircraft’s long-term viability. Official comments from industry authorities consistently underscore that the engine has attained its designated thrust level of approximately 8,000 kilograms-force during bench and apparatus testing.

Nevertheless, certain publications have asserted—without citing official documentation—that the engine has not yet attained its maximum design capabilities under operational conditions, especially when the aircraft is completely loaded. These assertions indicate that further modifications to the powerplant might be necessary, potentially leading to a delay in certification.

It is noteworthy that none of the principal stakeholders—Rostec, UEC, UAC, or Rosaviatsiya—have publicly acknowledged such deficiencies. Their stance continues to be that certification is moving forward in accordance with regulatory procedures and test outcomes. The lack of official comments regarding unverified claims is a common practice in aerospace programs, as premature assertions may distort public perception.

It is evident that the PD-8 continues to be subjected to flight testing over a broad range of operating conditions. Certification authorities are required to verify not only the maximal thrust output but also the reliability, fuel efficiency, thermal stability, and performance under adverse conditions prior to granting approval.

Flight Testing and Environmental Certification

As of 2026, flight testing continues with several experimental SJ-100 aircraft stationed at the Ramenskoye airfield in Zhukovsky. These aircraft demonstrate various phases of import substitution and system integration, enabling engineers to validate both transitional and nearly complete configurations.

One aircraft remains equipped with SaM146 engines and has undergone partial replacement of imported systems, serving as a baseline reference. Another is fitted with PD-8 engines and a combination of domestic and legacy components. The most advanced prototype features PD-8 engines and a near-complete substitution of imported components, reflecting the intended production standard.

A crucial testing phase scheduled for early 2026 will involve flights conducted in natural icing conditions in Arkhangelsk. These tests are compulsory for certification and cannot be entirely replicated within laboratory settings. Performance under frost conditions directly impacts flight safety and operational dependability, rendering this stage both time-critical and indispensable.

Production Infrastructure and Industrial Preparedness

Certification alone cannot guarantee prompt deliveries. Equally crucial is the preparedness of the production infrastructure to efficiently manufacture engines and components on a large scale. Rostec has consistently underscored that deadlines are dependent not only on the successful completion of flight tests but also on the industrial capacity to manufacture certified components on a mass production scale.

Establishing domestic manufacturing facilities for systems previously imported entails more than merely the tangible production process. It necessitates the implementation of quality control systems, comprehensive traceability documentation, personnel training, and regulatory supervision. Any delay in these areas may result in postponements of deliveries even after certification has been obtained.

Nevertheless, commercial-standard SJ-100 aircraft are currently under assembly, reflecting confidence that certification will be attained within the anticipated timeframe. This concurrent methodology—testing concurrently with production—enables manufacturers to reduce the interval between certification and initial deliveries.

2026 Delivery Schedule and Introduction into Service

Current baseline plans for 2026 foresee the delivery of approximately twelve SJ-100 aircraft to consumers. This figure indicates a gradual increase rather than full-scale production, in line with the aircraft’s first year of certified operation.

Following the issuance of certification, airlines will necessitate an approximate three-month preparatory period to conduct training for pilots, cabin attendants, and maintenance staff. The SJ-100 integrates new systems and procedures that differentiate it from previous Superjet variants, requiring updated training programs and documentation.

As a consequence, although deliveries may commence earlier in the year, large-scale commercial operations are more likely to begin toward the end of summer 2026. This phased introduction mitigates operational risk and enables airlines to progressively incorporate the aircraft into their fleets.

Implications for the Regional Aviation Sector

For the regional and short-haul sector, the SJ-100 assumes a critical strategic function. Delays in its entry into service have compelled airlines to modify their fleet renewal strategies and prolong the operational lifespan of older aircraft. However, upon commencement of operations, the SJ-100 provides a domestically supported alternative specifically designed to suit Russia’s route network and infrastructure.

The importance of the aircraft transcends immediate commercial factors. It functions as a benchmark for Russia’s capacity to maintain a contemporary civil aviation industry amidst circumstances of technological isolation. Success with the SJ-100 will have a direct impact on confidence in forthcoming projects and the wider reorganization of the aerospace industry.

Final Remarks

The outlook for the SJ-100 in 2026 is characterized not by missed deadlines, but by the challenges inherent in remaking an aircraft ecosystem from within. Certification timelines have been extended from late 2025 to early 2026 due to the necessity of test results, industrial readiness, and regulatory compliance—rather than an interruption in the program’s progress.

If certification of both the SJ-100 and the PD-8 engine is achieved according to plan in the first quarter of 2026, and if manufacturing infrastructure continues to develop concurrently, the aircraft is poised to begin commercial operations by mid-to-late 2026. In doing so, it will represent an important milestone for Russian civil aviation and the sustained viability of domestically manufactured passenger aircraft.